How do emergency shelters get fresh air?

How do emergency shelters get fresh air?

If you must go into an emergency shelter, then you can bet that conditions outside are not good, whether it’s a natural disaster, war or safety from criminal activity. You can store many supplies such as food and water for staying in a shelter, but without clean air, survival will only be minutes instead of days, weeks or months! There are a number of things that air and ventilation systems need to accomplish for shelters:

Providing a positive pressure at all times so that contaminated air from leaks or outside sources does not enter the shelter.

Filtering out contaminants such as nuclear, biological, chemical (NBC) or smoke toxins.

When the shelter must be completely closed up due to bad air quality outside, two things must happen:

Removing carbon dioxide (CO2) byproducts of the people residing in the shelter.

Providing supplemental oxygen to replace the oxygen depleted by residents

Let’s go through these in order. When the shelter is not being used or only tested during good external conditions, then its ventilation system can operate like your home system: bring in outside air, send it through filter(s) to remove dust and normal microbes like mold and bacteria, and keep a slight “overpressure” of 0.3 inches of water so that leaks in the shelter’s walls and doors will only cause air to move out, never in. The exhaust “vents” are really one-way valves that only let air go out, so that air coming in is controlled. They also protect residents of the shelter from any explosive “blast” of pressure and debris. For this reason, they are called overpressure blast valves.

The flow of fresh air should be similar to what is required at home: according to US standards, that is 0.35 air changes per hour (ACH) or 5 cubic feet per minute per person, whichever is greater (5 cfm is the specified minimum required by the US military, whereas 15 cfm is the recommended supply for ventilation in residential and commercial buildings). That said, 5 cfm is usually the design criteria to remove the moisture and carbon dioxide (CO2) that shelter residents exhale, and make them feel comfortable. The air intake must be protected from water and animal intrusion and sufficiently distant from the exhaust (overpressure blast valve) so that used air is not recycled through the shelter. Routing airflow through the shelter ensures that the exhaust is in the airlock (the chamber where residents enter and exit) so that any outdoor contamination is flushed out with the positive air pressure.

NBC filtration (or as the military defines it CBRN: Chemical, Biological, Radiological, and Nuclear) requires unique filter material. Pre-filters are used to keep dust and particulates out of the airstream, and then activated carbon impregnated with specific minerals is used to adsorb gasses that may be emitted during disasters or wars. For example, the activated carbon may be mixed or “doped” with potassium permanganate, potassium iodide, or magnesium dioxide or copper dioxide (see our article on what these materials remove from air). These are not typical systems used in home ventilation, as the activated carbon must be in sufficient purity and quantity to allow filtration for a number of days until outside air clears.

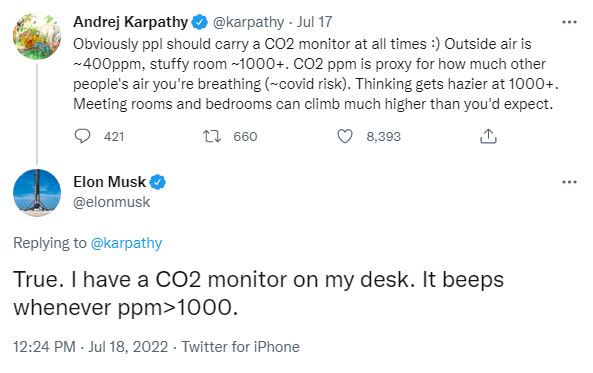

In the event that outside air is heavily contaminated, the ventilation system will need to be completely sealed off and the shelter will operate more like a submarine, where supplemental oxygen is added and CO2 is removed. The atmosphere needs to be maintained close to ambient outdoor air, at 19.5% oxygen and less than 0.2% (2000 ppb) CO2, and that’s a complex task when humans are using oxygen and expelling CO2 every minute! It’s good in this case to use the same two principals we introduced in our article on submarines: use good instruments to measure the air quality and have redundant systems to ensure that each function is maintained in case of system failure. In well-planned shelters, it’s common to have the following instruments: thermometer, humidity meter, differential pressure gauge (to maintain 0.3” water overpressure), smoke alarm, low oxygen detector, carbon monoxide alarm, carbon dioxide alarm, and a radon meter. (NBC Air Filtration Systems)

Although NBC filtration systems can be expensive, systems for adding oxygen and removing CO2 are even more expensive and complex. Here are some ways that military and professional systems do it (Air Supply Principles in Isolated Shelters & Chambers):

Supplemental Oxygen is available in three different methods:

Oxygen can be stored in a gas form under pressure or as liquid oxygen in cylinders, and released from these tanks when needed.

Oxygen generators can separate oxygen from compressed air stored in the tanks, or even generate oxygen from electrolysis of water (passing an electric current through it).

Oxygen “candles”, also called chlorate candles, are a very hot-burning cylindrical candle that actually puts out oxygen instead of consuming it.

Removal of CO2 requires even more chemistry. On average, each person produces 1 kg of CO2 per day, and buildup of CO2 in the air is lethal (see our article on CO2 levels). Therefore one or more of the following systems is needed:

CO2 scrubbers use a soda lime or lithium hydroxide material to remove CO2 from the airstream, but they produce a lot of moisture and heat and require space for storage of filters and material, which could be prohibitive for smaller bunkers.

Regenerative carbon-dioxide removal systems use a solid amine material and are advantageous in terms of space required, but have a high energy consumption and are costly to install.

Since air supply is one of, if not the most, critical aspects of a shelter, these systems are best designed and installed by professionals who have experience. In the survival shelter industry, NBC filter systems made by Israeli and European (Finnish and Swiss) companies differ significantly from those made in the US and UK. The former systems are more robust, with significantly better materials, engineering and more generous carbon supply than others. (NBC Air Filtration Systems)

Due to threats of war, disease and scarcity, many people are becoming interested in emergency shelters, but an improperly designed or constructed shelter can be more life-threatening than life-saving! If you are interested in building or buying an emergency shelter, we recommend you check out this article and research first. Having a place to retreat in emergency requires a lot of forethought and planning to truly make it "safe"!

Photo by Billy Freeman on Unsplash