Increasing Filter Surface Area for Better HVAC Filtration

Increasing Filter Surface Area for Better HVAC Filtration

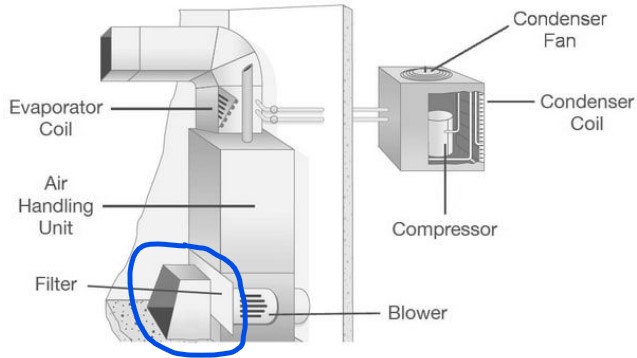

Lots of customers are jumping on the idea to use their central HVAC as a whole-house air cleaner. Why not? It’s a very expensive piece of equipment, it has a fan and an air filter, and it circulates air throughout the house. The only thing is that you can’t snatch out your 1” MERV 2 filter and throw in a MERV 12 one. At the least, the unit will protest by whistling, or delayed starts and stops, and at the worst you could cause damage it or cause a fire. Whoa! Let’s make the conversion to a whole-house air cleaner SAFELY.

We’ve written another article on how to increase filtration with your HVAC and why it’s dangerous to increase MERV without increasing filter surface area. Doing this increases the pressure drop, throwing a restriction into the airflow of the system. Basically, HVAC systems are not designed to have more than 0.25 inches water gage pressure drop over the filter (manufacturers recommend on average a 0.1 inch water gage over the filter), and adding a high MERV filter in the same slot as a low MERV filter will drastically increase the pressure drop.

Now, you can train that dog to hunt–just put in some extra equipment! What we’re talking about is more filter surface area. Here’s a great rule of thumb to keep in mind: when the filter surface area in a system is doubled, the pressure drop over the filters will typically reduce by more than 50 percent. (Duct Dynasty: Confronting Restrictive Air Filters) Another rule of thumb is to keep the filter face velocity between 200-250 feet per minute. This allows the air enough time to interact with the filter and effectively remove even fine particles. Here’s a great video explaining the concept; even though the instructor is using an app that HVAC techs use (measureQuick), he explains the filter face velocity concept beautifully. The difference between his velocity range (250-500 feet per minute) and ours (200-250 feet per minute) is that he’s working with commercial systems, so according to residential IAQ gurus, you’ll want to keep it between 200-250 feet per minute..

Ok, so I need to add more surface area to my filters–what options do I have?

- Adding another return grille: You can examine the layout of your current HVAC return duct and air handler to see if there is room to add another return grille, where you can place another filter. This may be the least expensive initial cost, however, over time thicker filters (see next option) may cost less. In order to calculate the required surface area of the additional filter, start with the cfm of your unit (see our article to determine, and divide it by 1) 200 ft/min and then 2) 250 ft/min. This will give your max and min surface area in feet squared. To convert these numbers to square inches, divide by 144. Then, subtract your current filter’s square inches to get the max and min square inches of the additional filter, and look at common filter sizes to fall in this range.

- A thicker filter: although the cross-sectional area of the face of the filter may remain the same, increasing from a 1” to a 4” filter adds a lot more surface area with those deep pleats! They are also called media filters. These thicker filters usually also require less frequent filter replacements. You will want to check the rated cfm and clean filter pressure drop for each model you consider. Here are some systems that fall into this category:

- If you have a 1” filter return filter grille on a wall somewhere, and there is enough room behind it (it doesn’t immediately narrow down), you can substitute a 4-5” thick filter for the 1” filter very easily using this type. See how the lip of the filter is designed to fit in the 1” grille, but you have a lot deeper filter behind it? Genius!

- Again, if you have deep space behind your 1” return grille, you can consider an Electronic Air Cleaner, which can increase MERV with the same surface area. For example, the Clean Comfort® brand AE14-G Series Electronic Air Cleaner, $600, claims "At rated airflow, the electronic air cleaner achieves a MERV 14 rating. With the fan running on low speed, the air cleaner increases efficiency up to a rating of MERV 16. The static pressure drop of the electronic air cleaner is as low as 0.16” compared to 0.22" or higher for a typical 1" MERV 8 furnace filter.”

- Install a cabinet air filter:

- Honeywell F100 Air Cleaners: At 6.25 inches wide, the cabinet is not super-wide, and it comes in 7 dimensions. For the 20x25” filter, the cabinet and filter are $168, and replacement filters are $40 each (when buying a 2-pack of MERV 11 filters). It’s recommended to replace the filter at least every 6 months, so $80 a year for filter changes is not bad! The clean filter pressure drop is 0.25 inches water gage for 2000 cfm.

- Aprilaire also makes a media filter. Their model 1210 is 20x25” and costs $120. MERV 11 filters for this unit cost $50 per filter (with a 2-pack). The clean filter pressure drop is 0.22 inches water gage for 2000 cfm.

- IQAir PerfectPro 2025 is a thick filter with nanofibers arranged for “hyperHEPA” filtration. It can drastically reduce the PM2.5 and PM10 in your home, as this test/review found, but the pressure drop at 2000 cfm (5 tons) is 0.32 inches water gage, which is very high! The price tag is also quite steep at $1,995.

- Trane CleanEffects Air Cleaner is an electrostatic filter. It uses ions to charge the incoming air to make particles more “sticky” on the filter. There are 3 parts to the air cleaner: a prefilter which should be vacuumed every 1-3 months, a field charger (with metal pins that generate ions) that should be cleaned by a technician, and a set of “reusable collection cells” which also get vacuumed by the homeowner. The pros: CleanEffects has the highest efficiency of particle removal with the lowest pressure drop, it has no filters to “replace”, and it’s Asthma & Allergy Friendly™ certified by the Asthma and Allergy Foundation of America. However, the cost for this device is about $2000 installed, and maintenance (cleaning) is key because its efficiency drops when it gets dirty. These units are only sold and installed by licensed HVAC technicians.

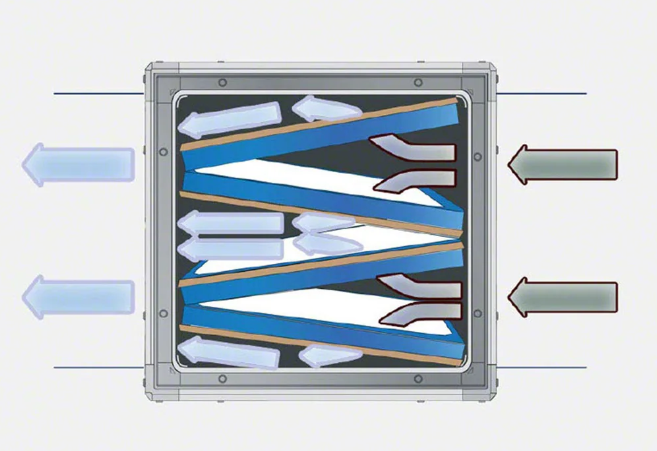

- A “V-Bank” of filters: Instead of placing one filter perpendicular to the air flow, you can get more surface area by adding 2 (or more) filters in the shape of a V. This device would usually be installed in an HVAC room (it’s not a filter grille for a wall). The only problem with this arrangement is that filter loading is not always even; air (like any fluid) will always seek the lowest pressure/resistance, and at the pointy ends where air becomes compressed, the filter load is lighter. There are several manufacturers that sell this type of filter arrangement.

- IQAir also makes a double-v-bank filter, meaning that it technically has up to 4x the filter surface area of a typical single, perpendicular filter installation (see picture below). This enables the device to exceed MERV 16, according to independent testing. The PerfectPro X 25x30 is compatible with a 5-ton HVAC system, the price tag is quite steep at $3,395, but you do get 3 years out of the filters. The pressure drop is similar to other systems at 0.22 in H2O at 2000 cfm.

- For a more economical V-bank filter system, AirScape SFB-V Series are MERV-13 V-Bank inline filter boxes. However, their largest unit is slightly undersized for our 2000 cfm system above. The SFB-V-16x25 costs about $374 and has a min-max airflow of 1667-2778 cfm, corresponding to 300-500 feet per minute face velocity and 0.12-0.29 pressure drop. Therefore, we would recommend you stay on the lower side and use this unit only in a 4 ton system (1600 cfm) to keep the face velocity down.

Source: IQAir Whole House Air Purifiers

If you want cleaner air with less filter changes, there are many options out there (we didn't include cabinets by Koch, GeneralAire and others simply because pressure drop information was not available). You’ll want to take into consideration ease of obtaining (purchasing) the filters, and also placement of the cabinet for ease of changing/cleaning them. Keeping up with filter changes is a worthwhile, minor chore if it means less dust in the house, less cleaning, and less allergens to potentially infect or annoy your family.

Photo by frank mckenna on Unsplash