How can I get more filtration with my current HVAC system? It’s a tug of war!

How can I get more filtration with my current HVAC system? It’s a tug of war!

At a staff meeting one day, one of our team members related how the HVAC company which installed the central AC system in his new home recommended using the lowest MERV filters available. I was shocked! Well, after thinking about it some more, I hypothesized they were waiting for his evaporator coil (the part that transfers absorbs heat from the air by transferring it to the cold refrigerant) to plug up so they could sell him a new system. In this day and age of availability of every type, face size and thickness of filter, a good HVAC company should be able to work with your existing system to get good filtration. Period.

If you’ve never heard of MERV, it is an acronym that stands for minimum efficiency reporting value, developed by the American Society of Heating, Refrigerating, and Air Conditioning Engineers (ASHRAE) in 1987. The range is from 1 to 20, and designates with what efficiency the filter removes small particles between 0.3 and 10 micrometers in diameter. (check out this post for more information on MERV). Generally you’ll want to get the highest rating possible (more filtration) for your system, without causing too much pressure drop, because in general, increasing the MERV increases pressure drop across the filter, while HVAC equipment manufacturers want you to stay with a low pressure drop of around 0.10 inches of water column (i.w.c.) across the filter. That’s the tug of war–but why aren’t HVAC installers figuring out how to give consumers, the ones who pay for new or upgraded systems, both? It’s like selling a delicious drink in a cup with a straw that’s too small to get it out at any satisfying rate (like a coffee stirrer). Sure, you could take out the straw and lid and risk getting it all over yourself as you drink it. However, even fast food chains and gas stations figured this out years ago: larger straw and cup= convenient way to drink, more satisfaction, more sales.

In this case, though, the consumer is left to bow to the advice of greedy or ignorant HVAC installers, or do research to figure it out himself. Yes, there is a way to get both high MERV and low pressure drop! You just need to install a larger filter. It sounds simple, right? Yet, because many installers are trained to recommend standard size, 1” filter frames, you’ll probably have to do the math and specify one yourself. Don’t get scared yet! We’re here to help with that calculation.

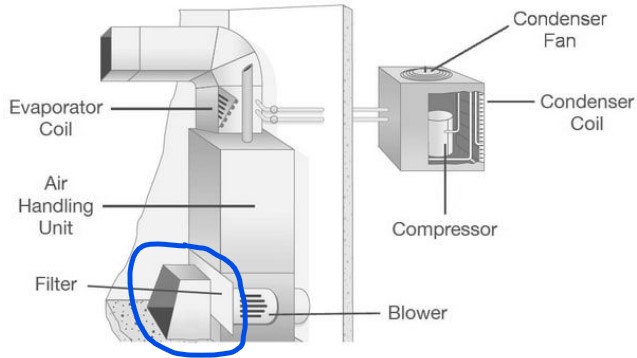

Here’s a diagram of the typical HVAC system so you know what we’re talking about/aiming for:

Image source: RemoveandReplace.com

The part we’re talking about is outlined in blue. The filter can be installed on the side of the HVAC closet door, in a ceiling or a wall. In the diagram the air is flowing through the filter, up through the air handling unit, through the evaporator coil, and out to various room registers/grilles. The whole system “sucks” air through that filter, and if it’s too small, it’s like sucking a Big Gulp through a coffee stirrer–the pressure drop or suction pressure is too much! Making the “face” of the filter larger will allow the velocity of the air through the filter to drop, which makes the pressure drop go down.

So, what is the magic size of filter that makes the pressure drop go down? That depends on the size of your HVAC system. This very helpful article from industry expert Allison Bailes gives the secret requirement:

Filter Area = 2.0 square feet (or more) for each 400 cfm of air flow

Since most filters are measured in inches, we can convert that formula to:

Filter size (sq. inches) = System Air Flow(cfm) x 288/400 OR

Filter size (sq. inches) = 0.72 x System Air Flow (cfm)

Like in any interesting math problem, this one has a formula with some knowns and some unknowns. The unknown is the filter size, and the known is the System Air Flow. To find the system air flow, you can do several things:

- Look at the HVAC air handler information specifications. If you don’t have the system specs, go to the air handler, take a photo of the sticker with the model number on it, and search for this model’s manual online. For example, I replaced my air handler recently with a variable-speed unit. It will shift fan speeds according to the heating or cooling load, with maximum 1200 cfm, 640 cfm intermediate, and 400 cfm minimum. Since the pressure drop will be maximum at the maximum air flow, I’m going with 1200 cfm.

- Approximate the air flow using the system tonnage: cooling units are often measured in the US by “tons”. According to HVACtrainingsolutions.net, 350 to 400 CFM per ton of cooling is required for proper air conditioning system operation. We’ll use 400 cfm to be conservative. If you know you have a 3 ton system, then 1200 cfm is the maximum airflow. This lines up with the specifications on my unit. (This equivalent of 400 cfm per ton can vary because of relative humidity, dry-bulb temperatures, wet-bulb temperatures, air density, mass flow rate, and elevation; if you want to “get technical”, check out this article!)

After you determine the cfm of your system, plug it into the filter size formula above. In my case, 1200 cfm x 0.72 = 864 square inches of filter. Yikes! My own filter (24”x24”) was undersized by a third, and when I measured the pressure drop at maximum fan speed (1200cfm) it was 0.25 inches water gage, which was fairly high for a clean filter. However, if I “upgraded” to a 24x36” filter that size fit my requirements exactly (864 square inches). The problem is that I don’t have room for such a big filter.

If you find that space or filter availability for bigger filters is a problem, you can solve it in a different way: add another return with another filter. Many homes have 2 returns, such as one upstairs and one downstairs. In this way, you’re getting the area and the filtration you need. Adding a second return lowers the airflow per return, and also changes the air circulation in your home. At the minimum, high MERV and high airflow will not be a problem! In my case, the easiest thing to do was look at the return air duct and add another grille in the only place I could: my bedroom. I ended up adding a 20x20 return air grill there, which lowered the pressure drop to 0.09 inches water gage for a clean filter, which eased the work of the fan unit and gave me more filtration.

This is the dilemma homeowners often face: accept the “expert” opinion of their contractor, or start doing their own research and demand equipment or installations that at least safeguard the equipment they are installing! Many installers mean well, but by not using standard equipment like manometers (pressure-sensing devices) they have no idea what the pressure drop over the filter is. They also don’t know what pollutants like dust, human and pet dander, and microbes are allowed into the new system by specifying low-grade MERV filters. Their ignorance or bad advice costs homeowners BIG when the air, and consequently the system, stays dirty. Just like we sometimes must do with our health and doctors, we hope that you take this information to your HVAC company and specify what you need to win the tug-of war and keep you and your family healthy!

Photo by Anna Samoylova on Unsplash