What is Inverter Technology and what does it do for my Air Conditioner?

What is Inverter Technology and what does it do for my Air Conditioner?

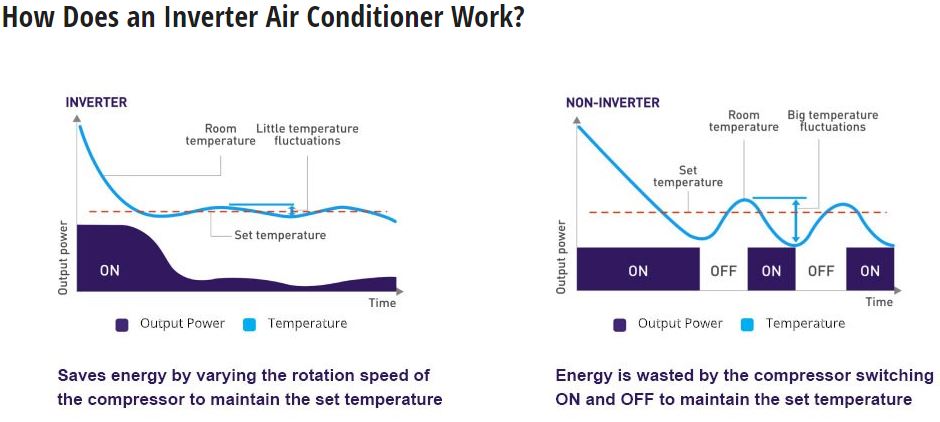

To start, let’s review the way conventional air conditioners work. You set your preferred temperature, and when the room gets too warm, a thermostat sensing the higher temperature will cause the air conditioner to come on. When the room is cooled properly, the air conditioner shuts off. The lag in turning on and off varies by unit, but it can be as much as two-three degrees: at a set point of 72 deg F, the air conditioner doesn’t come on until the room warms up to 73, and doesn’t shut off until the room is cooled to 71 deg F or lower. In the case of inverters in air conditioners, they can keep the room at an even 72 all day long by running continually with lower power input. The best way to explain them may be the example of cruise control in a car. If you try to keep the car at a steady speed, you’ll need to depress the gas pedal when you see the car decelerating, and let up when it goes over your target speed. Letting the car’s computer keep the speed is actually more gas efficient, because it will sense speed fluctuations sooner, and meter the gas pedal more accurately than you can! Here is a pictorial by Panasonic:

Once again, the power of computers is making our lives better by modulating the power consumption of the unit and avoiding those annoying temperature swings. But wait–there’s more! With only a 2-3 degree temperature swing with a traditional air conditioner, why does it feel like one minute you need an iced drink, and the next you need a sweater? It just doesn’t seem like that should happen with only 2-3 degrees. The answer lies in the humidity of the air. Temperature fluctuations cause the relative humidity (RH) to fluctuate, which makes a big difference in comfort levels! Humidity gets taken out of the air as it passes over the evaporator coils, and this is an important function of the air conditioner, because as you cool the temperature, RH will go up. If you don’t have a non-inverter air conditioner sized just right (having the optimal compressor power and refrigerant for the size of room), it will run for too long or too short, causing the RH to fluctuate:

- Too large of a unit means it will run for short cycles, cooling the room quickly but not running long enough to remove adequate moisture from the air.

- Too small of a unit means that it will run for long periods of time and humidity will go down, but jump right back up when the unit shuts off.

The inverter air conditioner not only keeps temperature constant, it can also keep humidity lower and constant. Here’s how that works:

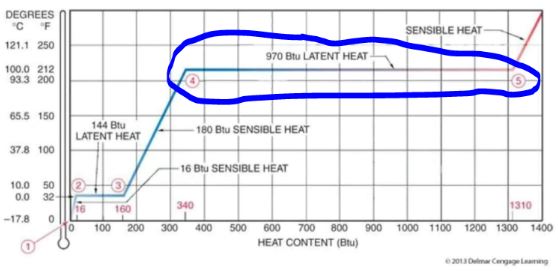

- Back to physics class: There are two kinds of heat: sensible and latent heat. Here is an excellent page to understand more, but basically sensible heat is related to changing the temperature of a body (in this case the air), and latent heat is related to the phase change of the body (in this case changing the water vapor in the air to liquid so that it will drain away).

- Constant speed on/off systems are good at removing sensible heat to lower the temperature of the air. However, they don’t do such a great job at removing latent heat (humidity) out of the air. This diagram shows why: it is a diagram of how much energy is needed to push water into a different phase. The long flat part at 100 deg C (212 deg F) shows how much energy is needed to change water from liquid to vapor, and once it is a vapor, the same amount of energy (970 BTU, or British Thermal Units) is needed to condense it back to a liquid, without even changing the temperature!

- So, when the system is set to only lower temperature, it does not continue to supply the needed energy to change the phase of the water vapor in the air to a liquid, to condense it out of the air. It will simply stop cooling when it hits the temperature set point.

- Inverter technology uses a computer and variable speed fan to slow down the speed of the air crossing the evaporator coil. When the air spends more time in the evaporator, more water vapor will condense out of the air, meaning more dehumidification occurs. It also uses a variable speed compressor to better control the flow of refrigerant through the system, because slowing the fan alone with a standard compressor may cause the coil to freeze. Since the system will be continually cooling instead of stopping and starting, a variable speed compressor allows for a small steady flow of refrigerant when the room is in a steady state (no one coming in or out or cooking, etc.), but also a ramp-up when someone opens a door or turns on an exhaust fan, etc.

This is all great information, but what if you have a central AC system that’s only a couple years old, and very little budget to go making changes? The good news is that it is possible to replace your standard single-speed blower motor with a variable speed motor. Here are some facts about this type of upgrade:

- The term “variable-speed” applies to two different components in an air conditioning or heat pump system: the blower motor and the compressor. A variable-speed blower can be matched with a single-speed compressor, but a variable-speed compressor must always be paired with an adjustable-speed blower. (therma.com)

- Single speed motors in blower units are generally called “PSC” or Permanent Split Capacitor, while variable speed motors are called Electronically-Commuted Motors (ECMs) or Brushless Permanent Magnet motors (BPMs). ECM is a trade name for BPM (BuildingScience.com)

- ECMs come in “3 flavors”: non-variable constant torque, variable constant torque, and variable constant flow. (David Butler, energyvanguard.com). If you are looking for better dehumidification, you may want to go for the Variable speed, constant torque model. The Variable speed, Constant Flow models are the most expensive.

- ECMs are quieter and use less electricity than PSCs.

- Retrofitting the blower fan has the following challenges:

- You’ll need to make sure the existing electrical service is compatible with the new ECM. Although the resulting operating current draw should be less than the PSC motor it replaced, you’ll need to check that the motor nameplate ratings don’t require upsizing the supply circuit in order to provide the necessary electrical safety. (Titus HVAC)

- The new motor may require a different type of mounting, ie. a “belly band” vs. a bracket, and the technician may need to use parts from several conversion kits to install it.

- The Building America program retrofitted PSC blower motors with ECM motors at 8 homes in upstate New York in 2013 as part of a study. The study did extensive screening of homes and systems so that only homes with the right size hp motors, the right size blower housing and cabinets, and the right type of motor mounts were chosen, making the install straightforward for the technicians (US Dept. of Energy). According to Titus HVAC, ECM retrofit doesn’t just mean replacing the motor. It generally means replacing the motor, the speed control, and blower assembly. It will likely also require additional components like power cables, communication cables, and a power filter. It could even require changing internal options like line and/or motor fuses.

- There are several manufacturers for these retrofit motors.

- The most well-known may be Regal Rexnord with the Genteq Evergreen motors, also offered on Amazon (this company purchased the ECM trade name).

- US Motors’ “HVAC Rescue Motors” series includes bluetooth-enabled motors and some that do not need the aforementioned airflow programming, making for an easier install.

- The Concept 3 motor used by the Building America Program is currently out of production.

- A knowledgeable HVAC technician can help you with the decision and options; don’t be afraid to get several opinions! Ask if he will be taking pressure and power readings before and after the install. This is key to getting your new motor running right, or preventing an ineffective change to the system. Here are two links for more information on pressure and power draw readings.

- Some states or power companies may offer rebates to retrofit your PSC with an ESM, such as this 2013 offer by Minnesota Power.

- ECMs will save power on systems that are set to have the fan always “On”, such as when a Whole-Home Polar Ionizer is installed. This type of purifier runs 24/7 and as such needs the fan to run 24/7.

If your whole HVAC system is nearing end of life (10 years or more), you may ask about replacing the blower and compressor with variable-speed units, which will give the best energy efficiency available in forced air units today. Some HVAC companies will try to sell what is easiest for them to install, or what their suppliers recommend, or what has always been done, but there is always room for improvement…keep searching and asking until you find it!